This is article four in a series of six published in Mining Magazine.

Explore the full original article here

Futurecasting an operation is fun, because it entails blending different technologies and exploring the physical impact on an environment.

In our last articles we explored two operating visions of the future: The Rock Factory and The Living Mine; both concepts derive from observable technology trends and present-day operating innovations.

A lot of future benefit, however, will come from how mines are run and organisations are designed rather than the finding, mining and moving of ore. The technology advancements that allow for the removal of people from hazards, and create continuous, flexible, more efficient operations, will both enable and require a new way of working.

They also raise new questions. What role will people have in the mines and what will the mining organisation of the future look like?

The Symbiotic Structure

Our third scenario, The Symbiotic Structure, paints a picture of what the mining organisation of the future will look like. It is a model we are getting closer to every day.

Here’s the good news for humans; while the need for our physical involvement inside the mines will diminish, we will still be needed to solve problems and manage the business. Companies, less able to differentiate through improving day-to-day operations, will shift their focus to the future and looking outwards. Since people will work with information and be less tied to the physical mine, it will be possible to locate them anywhere.

In the future, employees will be focusing on one of three areas: prediction and planning, monitoring and maintenance, and demand and delivery.

Prediction and planning

Edward de Bono, of Thinking Hats fame, stated that: “In the future, instead of striving to be right at a high cost, it will be more appropriate to be flexible at a lower cost. If you cannot accurately predict the future, then you must flexibly be prepared to deal with various possible futures.”

Exception-driven, big-data enabled operations will elevate management thinking from daily operational fire-fighting. Management will focus on how to avoid future challenges, such as options to rebalance production around possible market demand fluctuations. This will involve strategic scenario thinking and real options thinking, as well as stochastic modelling and a better understanding of the societal, regulatory and macroeconomic drivers that create demand.

Monitoring and maintenance

Humans will design, program and maintain the machines that operate mines. As in the Rock Factory, even if machines operate on an independent basis, people will still be needed to maintain them.

Humans will also need to intervene (but only when the system indicates that an ‘exception’ has occurred) when the machines don’t work or hit a snag that their programming cannot overcome.

Demand and delivery

Machines may do nearly everything else for us, but managing, interacting and predicting human needs is a job best done by humans. Demand and delivery employees focus on understanding, managing and meeting the demands of the external market.

These employees interact with the outside world, including stakeholders and customers to balance supply and demand and better align corporate needs with stakeholder needs. They set the parameters for product development and operations, manage vendors and logistics issues and ensure that production meets demand.

No matter how much technology takes over, the power of human creativity and the comfort that a name, handshake and a smile carry will still have currency in the future.

Operating in this new environment

The well-worn concept of a remote operating centre as a centralised control room with centralised people will morph into something much more decentralised and broader in scope and scale.

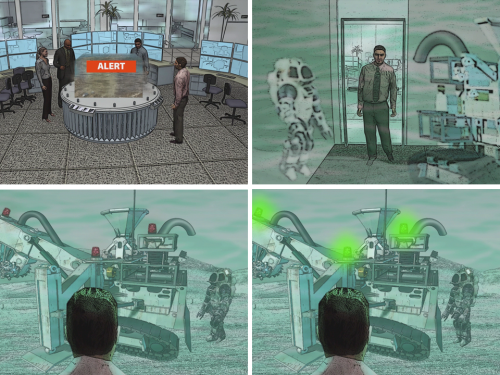

Enabled by virtual reality and immersion technology, people will be able to work and connect to anything from anywhere in the world. Mines will operate 24/7 with continuous, remote management shifts from time zone to time zone to match production.

Miners will look idler than they do today. Instead of actively moving ore, they will watch and monitor for exceptions and variability, addressing issues as they surface. When they do surface, teams will collaborate around factual data to solve problems. Engineers, production managers, customer-facing resources and vendors will come together virtually to define, develop and deliver solutions in real-time.

Once solutions are developed, immersion technology or human-machine convergence will allow physical maintenance to be performed remotely. Operators will be able to visit the mining environment by inhabiting the machines themselves, whether in a pit, underwater or deep underground in a nano-machine. The technology will enable them to see, hear and feel as if they were at the mine site, without ever leaving the office environment.

Glimmers of possibility

Much of this thinking has already been put to test in one form or another, although less so in mining than in many industries. There are many examples including:

- Decentralised operating centres and virtual reality: Used daily by a variety of industries such as oil and gas exploration and transportation, remote operating centres enable the control of everything from underground drill bits to the monitoring of large truck fleets, from halfway around the world. Virtual-reality rooms, enabled by blending technologies such as Oculus Rift, Kinect VR, advanced processors and haptic feedback, allow organisations to enter immersive environments to command and control.

- Integrated and collaborative decision making: The same oil and gas companies make decisions by gathering impromptu groups together from various companies, regardless of where they are in the world. Using real-time net-present-value calculations that take into account the latest information and expected future scenarios, all participants see the same data to collaboratively make key decisions. We are using the same collaborative scenario-driven thinking today with consumer products, heavy industry and even some mining companies.

- Managing by exception and predictive analytics: Predictive analytics have already come to parts of the mining industry through companies such as GE, often within the maintenance function. In addition, most of our future visions adopted by leading miners involve remote-controlled systems that allow machines to operate semi-autonomously, with people becoming involved only when there is an error or an issue to be addressed.

Enabling new business models

As mining operations change, so will their management. People will be able to focus on areas of the business that are only given cursory attention today. This will change the way we work.

These developments will enable new business models and new ways of thinking about how mining companies extract value.

Next month we will explore ‘The Fluid Firm’ and how the mining company of the future may not look like the mining company of today.

The Stratalis Group is a full-service strategy and innovation consultancy focused on helping companies in the resource industry to discover, develop and deliver new pathways to growth, increased profitability and ROI. See: www.stratalisgroup.com